China wholesale Graphite Flake Powder - Purity Graphite Powder with Perfect High Thermal Conductivity – Rubang

China wholesale Graphite Flake Powder - Purity Graphite Powder with Perfect High Thermal Conductivity – Rubang Detail:

Products Quick Details

Product Name: Graphite Flake Powder

Place of Origin: Hebei, China

Brand Name: Rubang Carbon

Model Number: RB-GP-1

Type: Artificial graphite powder

Raw Material: Graphite electrode scrap

Application: Refractory, Casting, Foundry

Sizes: Customized

Superiority: High Carbon Amorphous Graphite Powder

Color: Black

Mode of Production: Extrusion, Vibration, Molded, Isostatic

Chemical Composition:

Fixed Carbon 98.5%Min

Volatile Matter 0.5%Max.

S: 0.05%Max. Ash 0.5%Max.

|

Graphite Flake Powder-Physical & Chemical Index |

||||

|

Description |

Unit |

Specifications(Mesh): 32/50/80/100/200/300/500/1000/1200 |

||

|

Amorphous |

Natural Flaky |

Expandable |

||

|

Appearance |

- |

Black Flake or wder |

||

|

Carbon |

% |

99.50 |

99.50 |

98.50 |

|

Electrical Resistance |

μΩ.m |

9-13 |

8-12 |

9-13 |

|

Real Density |

g/cm3 |

2.05-2.2 |

2.05-2.2 |

2.05-2.2 |

|

Bulk Density |

g/cm3 |

1.05-1.15 |

1.05-1.15 |

1.05-1.15 |

|

Porous Rate ≥ |

% |

45 |

35 |

50 |

|

Sulfur ≤ |

% |

0.02 |

0.03 |

0.02 |

|

Ash ≤ |

% |

1.5 |

0.5 |

0.5 |

|

Moisture ≤ |

% |

0.2 |

0.3 |

1.0 |

| Note: The Ash are parameter indexes. | ||||

Products Description:

1)Amorphous Graphite Powder:

The Amorphous Graphite Powder product is made from the High quality low ash petroleum coke as raw materials, processed at high temperature above 2800 °C vacuum heat treatment. It has a high carbon content, low hardness, withstand high temperature, large porosity, low thermal conductivity, improve adhesion, stable friction coefficient.

2) Natural Graphite Flaky Powder:

The Natural Graphite Powder product has the properties of high-quality natural crystalline flake graphite, oxidation resistance at high temperature, self-lubrication and plasticity;

as well as good electrical conductivity, electro heat property and adhesion. Application: used as a demoulding lubricant – production of catalyst in chemical fertilizer industry;

High-temperature lubricant base stock and anticorrosion lubricant base stock; Powder metallurgy release agent and alloying component additive; The filling agent or improving agent of rubber, plastic and composite.

3) Expandable Graphite Powder:

The Expandable Graphite Powder product has excellent expansibility and high temperature resistance, heat insulation, lubricity and chemical stability.

Application: Thermal insulation material additive in metallurgical industry; Raw Materials of Flexible Graphite Paper; Battery Absorbent Material; Lubricant Additive; Extinguishing Agent Additive.

Features:

Stable, complete crystallization, good toughness, strong resistance to friction, Ultrafine conductive, Thermal Shock resistance, the Features of high temperature resistance, hot insulation, lubrication and chemical stability.

Applications:

(1) as the additive of metallurgical industry.

(2) as the materials of flexible graphite.

(3) as the absorbent materials of battery.

(4) used for additive of lubricant.

(5) used for additive of refractory.

Business Conditions and Terms:

Prices and Delivery Terms: FOB, CFR, CIF, EXW, DCA, DDP

Payment Currency: USD, EUR, JPY, CAD, CNY, AUS

Payment Terms: T/T, L/C, D/P D/A, Western Union, Cash

Loading Port: XINGANG or QINGDAO, CHINA

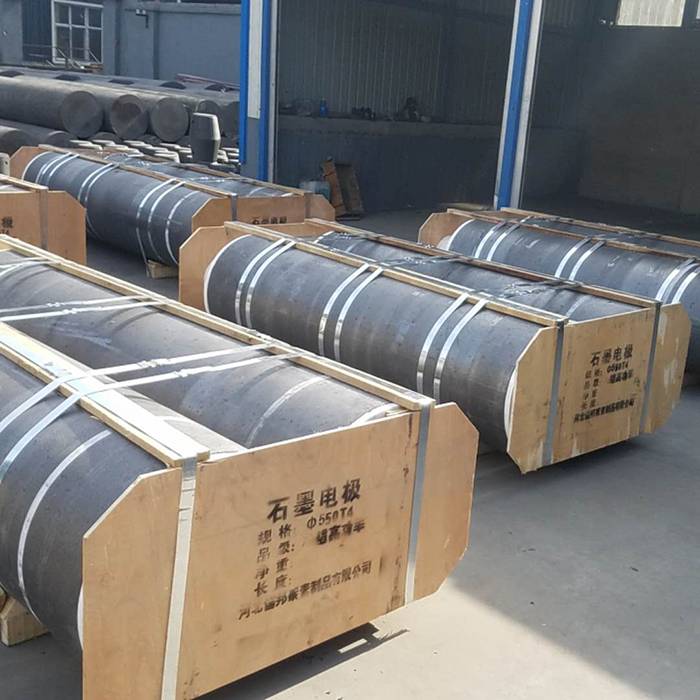

Packing Details:

Ton bags or 10/20/25kg in 1MT Big Bags, or Waterproof jumbo Bags.

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for China wholesale Graphite Flake Powder - Purity Graphite Powder with Perfect High Thermal Conductivity – Rubang , The product will supply to all over the world, such as: Thailand, Thailand, Palestine, We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!